Rea u amohela ho buisana le ho buisana

Mochini oa Thermoforming oa RM-4 oa liteishene tse 'ne

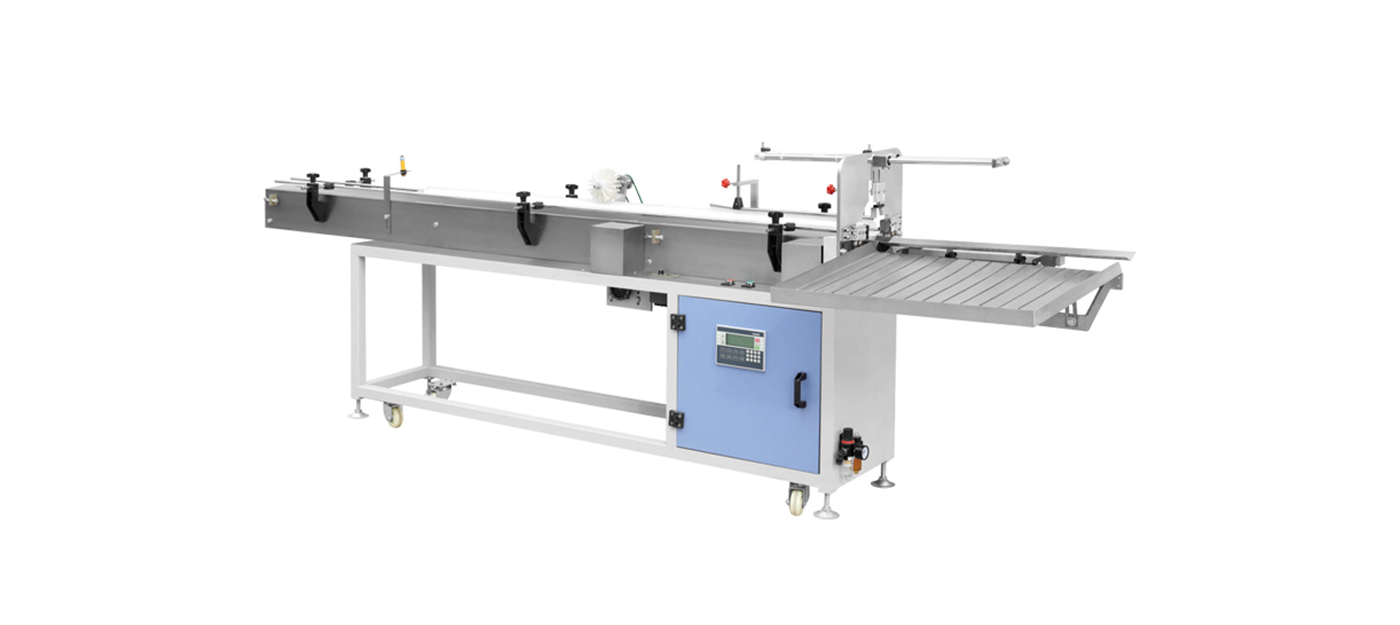

Tlhaloso

Mochini oa thermoforming oa 4-station positive and negative pressure ke sesebelisoa se sebetsang hantle sa tlhahiso se ka sebelisetsoang ho hlahisa mabokose a litholoana a polasetiki a lahloang, lipitsa tsa lipalesa, likoahelo tsa senoelo sa kofi le li-lids tse nang le masoba, joalo-joalo. Thepa ena e amohela theknoloji e ntle le e mpe ea khatello ea thermoforming ho sebetsana le pampiri ea polasetiki ka sebopeho se hlokahalang, boholo le moralo o lumellanang oa ho phunya ka ho futhumatsa letlapa la polasetiki le ho hatella khase e ntle le e mpe ea khatello. Thepa ena e na le lihlopha tse 'nè tsa li-workstations bakeng sa ho theha, ho phunyeletsa ka lesoba, ho phunyeletsa ka bohale, le ho bokella le ho pata, tse ka finyellang litlhoko tsa liindasteri tse fapaneng le ho netefatsa boleng le botsitso ba lihlahisoa.

Mechine ea Parameters

| Sebaka sa ho bopa | Matla a ho kokobetsa | Lebelo la ho matha | Botenya ba maqephe | Bophahamo ba ho theha | Ho theha khatello | Lisebelisoa |

| Max. Hlobo Litekanyo | Matla a Tlatsetsang | Dry Cycle Speed | Max. Leqephe Botenya | Max.Foming Bophahamo | Max.Moea Khatello | Boitsebiso bo Loketseng |

| 820x620mm | 80T | 61 / potoloho | 1.5 limilimithara | 100mm | 6 Bar | PP, PS, PET, CPET, OPS, PLA |

Likaroloana

Taolo e iketsang

Thepa e nka mokhoa o tsoetseng pele oa ho laola othomathike, o ka laolang ka nepo maemo a kang mocheso oa mocheso, nako ea ho bopa le khatello ho netefatsa botsitso le botsitso ba mokhoa oa ho bopa.

Ho fetoha ha hlobo ka potlako

Mochine oa thermoforming oa 4-station o na le mokhoa o potlakileng oa ho fetola hlobo, o thusang ho fetoha ha hlobo ka potlako le ho ikamahanya le litlhoko tsa tlhahiso ea lihlahisoa tse fapaneng, ka hona ho ntlafatsa ho fetoha ha maemo.

Ho boloka matla

Thepa e sebelisa theknoloji e tsoetseng pele ea ho boloka matla, e fokotsang tšebeliso ea matla ka katleho, e fokotsa litšenyehelo tsa tlhahiso, 'me ka nako e ts'oanang e boloka tikoloho.

Ho bonolo ho sebetsa

Mochini oa 4-station thermoforming o na le sebopeho se hlakileng sa ts'ebetso, se bonolo ho sebetsa le ho ithuta habonolo, ho fokotsa litšenyehelo tsa koetliso ea basebetsi le litekanyetso tsa liphoso tsa tlhahiso.

Kopo

Mochini oa 4-station thermoforming o sebelisoa haholo indastering ea ho paka lijo, 'me o loketse haholo-holo likhoebo tse hlahisang lihlahisoa tsa polasetiki ka tekanyo e kholo ka lebaka la ts'ebetso ea eona e phahameng, bokhoni bo phahameng le ho feto-fetoha ha maemo.

Thuto