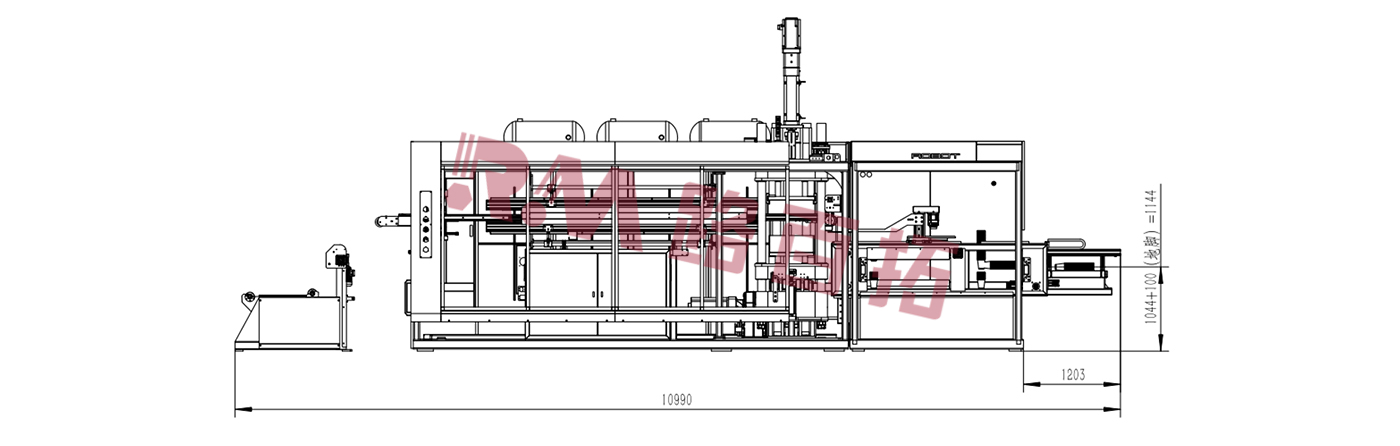

RM 2RH Double Station IMC Thermoforming Machine

Mechine ea Parameters

| ◆Mohlala: | RM-2R |

| ◆Max.Sebaka sa Moetso: | 820*620mm |

| ◆Max.Ho Etsa Bophahamo: | 80 limilimithara |

| ◆Botenya ba Leqephe(mm): | 2mm |

| ◆Max Air Pressure(Bar): | 8 |

| ◆Dry Cycle Speed: | 48/cyl |

| ◆ Claping Force: | 65T |

| ◆Motlakase: | 380V |

| ◆PLC: | KEYENCE |

| ◆ Servo Motor: | Yaskawa |

| ◆Mofokotsi: | GNORE |

| ◆Kopo: | literei, lijana, mabokose, likhurumetso, joalo-joalo. |

| ◆Likaroloana tsa mantlha: | PLC, Enjene, Bearing, Gearbox, Motor, Gear, Pump |

| ◆ Boitsebiso bo Loketseng: | PP.PS.PET.CPET.OPS.PLA |

| Max.Hlobo Litekanyo | Matla a Tlatsetsang | Dry Cycle Speed | Max.Leqephe Botenya | Max.Foming Bophahamo | Max.Moea Khatello | Boitsebiso bo Loketseng |

| 820x620mm | 85T | 48 / potoloho | 2.8mm | 180 limilimithara | 8 Bar | PP, PS, PET, CPET, OPS, PLA |

Video ea Sehlahisoa

Setšoantšo sa mosebetsi

Likarolo tse ka Sehloohong

✦ Eba le boemo bo bocha ba tlhahiso ka mochini oa rona oa morao-rao oa ho Etsa le ho Seha o Lebelo le Leholo.E na le moralo oa liteishene tse peli, e sebetsa ho theha le ho seha ka nako e le 'ngoe, e matlafatsang katleho ea tlhahiso.Sistimi ea ho itšeha ha in-die e netefatsa ho khaola ka potlako le ka nepo, ho etsa hore ts'ebetso ea tlhahiso e atlehe haholoanyane.

✦Moetso oa rona o fana ka bokhoni bo botle le bo bobe ba ho theha khatello.Ka ho sebelisa mocheso le khatello, letlapa la polasetiki le fetoloa sebopeho sa sehlahisoa se lakatsehang.Ho theha khatello e ntle ho tiisa bokaholimo ba sehlahisoa bo boreleli, ha khatello e mpe e etsa bonnete ba ho nepahala ha likarolo tsa concave le convex, ho fella ka boleng bo tsitsitseng le bo phahameng ba sehlahisoa.

✦ E na le sistimi ea marang-rang ea marang-rang, mochini oa rona o fihlella ho bokella lihlahisoa tse felileng.Ts'ebetso ena e ntlafalitsoeng ea ho bokellana e ntlafatsa ts'ebetso ea tlhahiso haholo mme e fokotsa matla a basebetsi, e lumellang sehlopha sa hau ho tsepamisa maikutlo mesebetsing e meng ea bohlokoa.

✦Mochini oa rona o loketse hantle bakeng sa ho hlahisa lihlahisoa tsa bolelele bo nyane joalo ka linoelo tsa soso tse lahloang, lipoleiti le likhurumetso.Leha ho le joalo, e ka ikamahanya habonolo le boholo le libopeho tse fapaneng tsa sehlahisoa.Ka ho fetola liforomo feela le ho lokisa maemo, ho ka etsoa lihlahisoa tse ngata.

✦ Tsetela ka katleho le boleng ka Mochini oa rona o Iketsetsang oa Ho Etsa le ho Seha o Lebelo le Leholo.Ho theha le ho itšeha ka nako e le 'ngoe, bokhoni ba khatello e ntle le e mpe, ho bokella ka boiketsetso, le ho feto-fetoha ha tlhahiso ea lihlahisoa - tsohle ka tharollo e le 'ngoe e matla.Lula ka pele ho tlholisano 'me u phahamise bokhoni ba hau ba tlhahiso ka mochini oa rona o tsoetseng pele!

Sebaka sa Kopo

Mochini ona oa liteishene tse 2 oa thermoforming o sebelisoa haholo indastering ea ho paka le ea phepelo ea lijo.Ka melemo ea eona le ho feto-fetoha ha maemo, e fana ka likhoebo tse nang le litharollo tsa tlhahiso ea boleng bo holimo le tse sebetsang hantle.

Thuto

Selelekela:

Thermoforming ke ts'ebetso ea tlhahiso e feto-fetohang le e sebetsang e sebelisoang liindastering tse fapaneng.Ho netefatsa tlhahiso e se nang moeli le boleng ba maemo a holimo, ho lokisoa ha thepa hantle, ho tšoara thepa e tala le tlhokomelo ke tsa bohlokoa.

Tokiso ea Lisebelisoa:

Pele o qala tlhahiso, netefatsa khokahano e matla le phepelo ea motlakase mochining oa hau oa 2-station thermoforming.Etsa tlhahlobo e phethahetseng ea ho futhumatsa, ho pholisa, litsamaiso tsa khatello, le mesebetsi e meng ho netefatsa ts'ebetso ea tsona e tloaelehileng.Kenya liforomo tse hlokahalang ka mokhoa o sireletsehileng, ho etsa bonnete ba hore li tsamaisana hantle ho thibela likotsi tse ka bang teng nakong ea ts'ebetso ea tlhahiso.

Tokiso ea Lintho tse tala:

Qala ka ho khetha letlapa la polasetiki le loketseng ho bōptjoa, ho netefatsa hore le lumellana le litlhoko tse khethehileng tsa morero.Ela hloko haholo boholo le botenya, kaha lintlha tsena li ama haholo botšepehi ba sehlahisoa sa ho qetela.Ka letlapa la polasetiki le lokiselitsoeng hantle, u rala motheo oa liphetho tse se nang sekoli tsa thermoforming.

Litlhophiso tsa Mocheso:

Bula karolo ea taolo ea mochini oa hau oa thermoforming 'me u behe mocheso oa mocheso le nako.Nahana ka litšobotsi tsa thepa ea polasetiki le litlhoko tsa hlobo ha u etsa liphetoho tsena.Lumella mochini oa thermoforming nako e lekaneng ea ho fihlela mocheso o behiloeng, ho etsa bonnete ba hore pampiri ea polasetiki e fumana bonolo bo lakatsehang le sebopeho sa sebopeho se nepahetseng.

Ho theha - Stacking :

Ka hloko beha letlapa la polasetiki le chesitsoeng pele holim'a hlobo, ho etsa bonnete ba hore le bataletse ebile le boreleli.Qala mokhoa oa ho bōpa, ho matlafatsa hlobo ho kenya khatello le mocheso ka nako e behiloeng, ka bohlale ho etsa lesela la polasetiki ka mokhoa oo le o batlang.Ka mor'a ho theha, tlohela polasetiki hore e tiee 'me e pholile ka har'a hlobo, e fetela ho tlhophiso e hlophisitsoeng e hlophisitsoeng bakeng sa palletizing e sebetsang hantle.

Ntša Sehlahisoa se Feletseng:

Hlahloba ka botlalo sehlahisoa se seng le se seng se felileng ho netefatsa hore se kopana le sebopeho se hlokahalang mme se latela maemo a boleng bo holimo.Tlhahlobo ena e hlokolosi e tiisa hore ke liqapi tse se nang sekoli feela tse tlohang moleng oa tlhahiso, e tiisang botumo ba hau ba bokhabane.

Tlhoekiso le Tlhokomelo:

Ho boloka ts'ebetso ea lisebelisoa tsa hau tsa thermoforming, sebelisa mokhoa o hlokolosi oa ho hloekisa le ho o hlokomela.Kamora ho sebelisoa, theola mochini oa thermoforming 'me u o hakolle mohloling oa matla.Etsa tlhoekiso e phethahetseng ea hlobo le lisebelisoa ho tlosa masala a polasetiki kapa maloanlahla.Kamehla hlahloba likarolo tse fapaneng tsa lisebelisoa ho netefatsa hore li sebetsa hantle, ho boloka tlhahiso e sa sitisoeng.