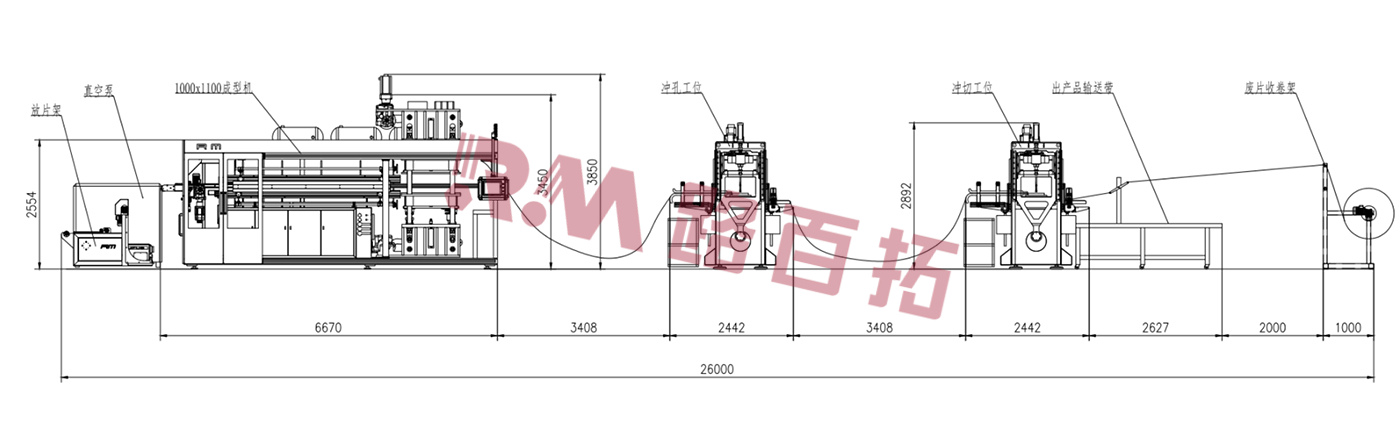

RM-T1011 + GC-7 + GK-7 Thermoforming Machine

Mechine ea Parameters

| ◆Mohlala: | RM-T1011 |

| ◆Mak.boholo ba hlobo: | 1100mm×1170mm |

| ◆Mak.sebaka sa ho theha: | 1000mm×1100mm |

| ◆Metsotso.Sebaka sa ho theha: | 560mmx600mm |

| ◆Mak.sekhahla sa lebelo la tlhahiso: | ≤25Times/mots |

| ◆Max.Ho Etsa Bophahamo: | 150 limilimithara |

| ◆ Bophara ba leqephe(mm): | 560mm-1200mm |

| ◆Mould ho falla sebaka: | The stroke≤220mm |

| ◆Mak.clamping force: | ho etsa-50T, ho phunya-7T le ho khaola-7T |

| ◆Phepelo ea motlakase: | 300KW(matla a ho futhumatsa)+100KW(matla a ho sebetsa)=400kw |

| ◆ Ho kenyeletsoa mochini oa ho phunya 20kw, mochini o sehang 30kw | |

| ◆ Litlhaloso tsa phepelo ea motlakase: | AC380v50Hz,4P(100mm2)+1PE(35mm2) |

| ◆ Sistimi ea lithapo tse hlano tsa mehala e meraro | |

| ◆PLC: | KEYENCE |

| ◆ Servo Motor: | Yaskawa |

| ◆Mofokotsi: | GNORE |

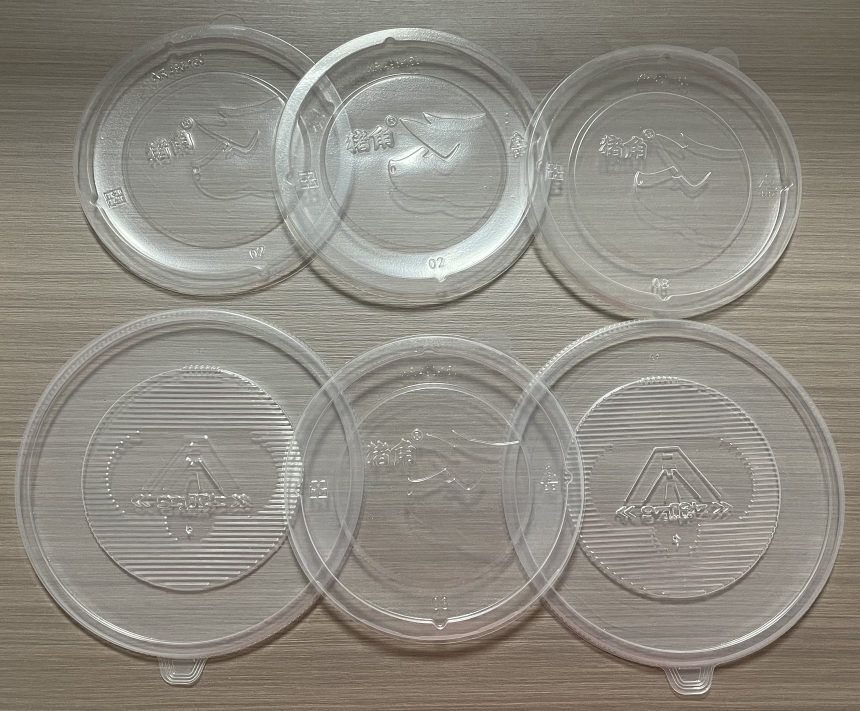

| ◆Kopo: | literei, lijana, mabokose, likhurumetso, joalo-joalo. |

| ◆Likaroloana tsa mantlha: | PLC, Enjene, Bearing, Gearbox, Motor, Gear, Pump |

| ◆ Boitsebiso bo Loketseng: | PP.PS.PET.CPET.OPS.PLA |

| Max.Mefuta ea hlobo | Matla a Tlatsetsang | Bokhoni ba ho Tebela | Ho Seha Bokhoni | Max.Ho theha Bophahamo | Max.Moea Khatello | Dry Cycle Speed | Max.Punching/ Boetsuwa ba ho poma | Max.Punching/ Ho poma kapele | Boitsebiso bo Loketseng |

| 1000 * 1100mm | 50T | 7T | 7T | 150 limilimithara | 6 Bar | 35r/mots | 1000*320 | 100 spm | PP, HI PS, PET, PS, PLA |

Video ea Sehlahisoa

Setšoantšo sa mosebetsi

Likarolo tse ka Sehloohong

✦ Tlhahiso e sebetsang hantle: Mochine o moholo oa thermoforming o nka mokhoa oa ho sebetsa oa mohala o tsoelang pele oa tlhahiso, o ka tsoelang pele le ka katleho ho phethahatsa mokhoa oa ho bōpa sehlahisoa.Ka mokhoa oa ho laola othomathike le ts'ebetso ea mochini o potlakileng haholo, ts'ebetso ea tlhahiso e ka ntlafatsoa haholo ho fihlela litlhoko tsa tlhahiso ea bongata.

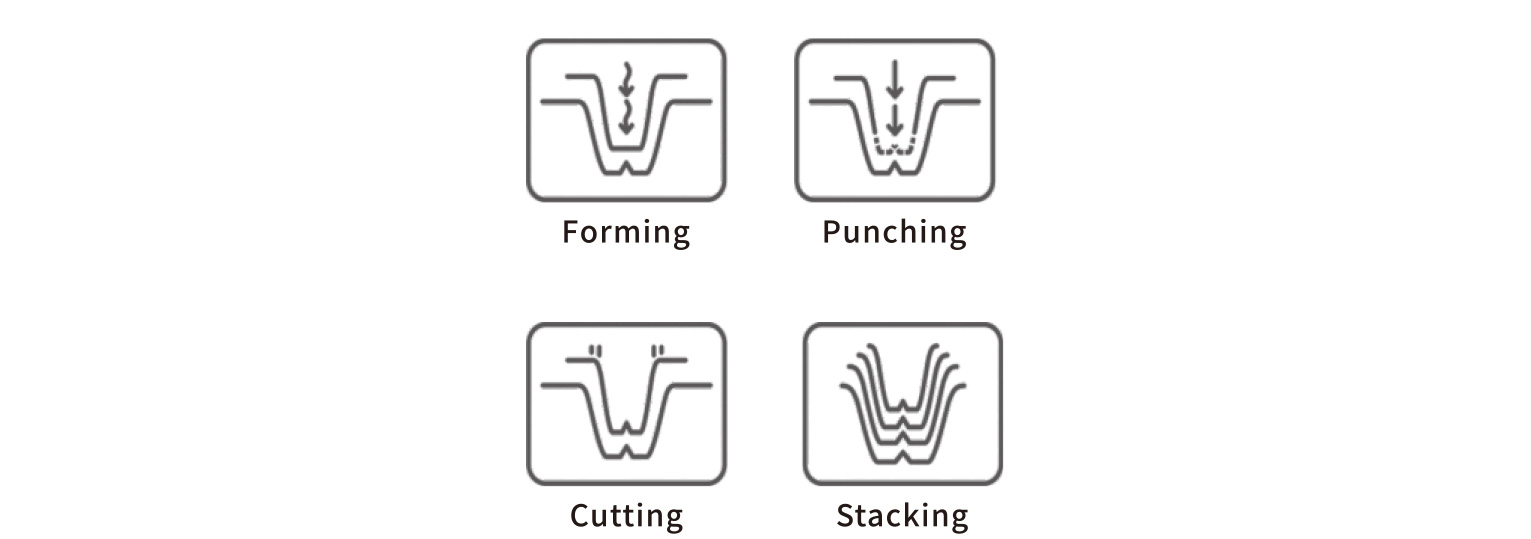

✦ Ts'ebetso e mengata: mochini o na le mesebetsi e mengata joalo ka ho theha, ho phunya, ho phunya ka bohale le ho kokota.

✦ Ho bopa ka nepo le lihlahisoa tsa boleng bo holimo: Mochini oa thermoforming oa sebopeho se seholo o sebelisa theknoloji e tsoetseng pele ea ho bopa, e ka laolang mocheso oa mocheso hantle, khatello le nako ea ho futhumatsa ho netefatsa hore thepa ea polasetiki e qhibilihile ka botlalo ebile e ajoa ka mokhoa o lekanang ka har'a hlobo, ka hona e etsa tlhahiso. lihlahisoa tse nang le boleng bo holimo le ho nepahala ha mahlakore.

✦ Opereishene ea othomathike le taolo e bohlale: Mochini o na le sistimi e sebetsang e ikemetseng, e ka hlokomelang mesebetsi e joalo ka ho fepa ka boiketsetso, ho etsa sebopeho ka othomathiki, ho otla ka boiketsetso, ho phunya ka mokhoa o iketsang le ho patisa ka boiketsetso.Ts'ebetso e bonolo ebile e bonolo, e fokotsa ho kenella ka letsoho, ho ntlafatsa haholo katleho ea tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso.

✦ Tšireletseho le ts'ireletso ea tikoloho: Mochine o moholo oa thermoforming o entsoe ka thepa ea boleng bo phahameng, e nang le nako e telele le botsitso.E boetse e na le sistimi ea ts'ireletso ea ts'ireletso ho netefatsa polokeho ea basebelisi.Ka nako e ts'oanang, mochini o na le moralo o bolokang matla, o ka fokotsang tšebeliso ea matla le ho fokotsa tšusumetso tikolohong.

Sebaka sa Kopo

Mochini o moholo oa thermoforming mochini oa RM-T1011 o sebelisoa haholo indastering ea lijo, indasteri ea ho paka lijo le indasteri ea thepa ea lapeng.Ka lebaka la ts'ebetso ea eona e phahameng, likarolo tse ngata tsa ts'ebetso le tse nepahetseng, e ka fihlela litlhoko tsa tlhahiso ea liindasteri tse fapaneng bakeng sa lihlahisoa tsa polasetiki le ho fana ka tšehetso e matla bakeng sa likhoebo ho ntlafatsa katleho ea tlhahiso le boleng ba sehlahisoa.

Thuto

Tokiso ea Lisebelisoa:

Ho qala mochini oa hau oa thermoforming, sireletsa mochini o moholo o tšepahalang oa thermoforming oa RM-T1011 ka ho netefatsa khokahano ea ona e sireletsehileng le ho o bulela.Ho bohlokoa ho hlahloba ka botlalo mochini o futhumatsang, o pholileng le oa khatello ho netefatsa ts'ebetso ea ona e tloaelehileng.Sireletsa mokhoa oa hau oa tlhahiso ka ho kenya liforomo tse hlokahalang ka hloko, ho netefatsa hore li tiisitsoe hore li sebetse hantle.

Tokiso ea Lintho tse tala:

Ho finyella phetheho ho thermoforming ho qala ka ho lokisetsa lisebelisoa tse tala ka hloko.Khetha ka hloko letlapa la polasetiki le loketseng hantle bakeng sa ho bōptjoa, 'me u netefatse hore boholo ba eona le botenya ba eona bo lumellana le litlhoko tse khethehileng tsa hlobo.Ka ho ela hloko lintlha tsena, u theha sethala sa lihlahisoa tse phethahetseng tsa ho qetela.

Litlhophiso tsa Mocheso:

Notlolla bokhoni ba 'nete ba ts'ebetso ea hau ea thermoforming ka ho hlophisa ka boqhetseke mocheso oa mocheso le nako ka phanele ea taolo.Iketsetse litlhophiso tsa hau hore li tsamaellane le lisebelisoa tsa polasetiki le litlhoko tsa hlobo, ho fihlela liphetho tse nepahetseng.

Ho theha - Ho phunya lesoba - Ho phunya ka mahlakoreng - Ho bokellana le ho patala:

Beha lesela la polasetiki le chesitsoeng ka bonolo holim'a hlobo, ho etsa bonnete ba hore e hlophisitsoe hantle ebile ha e na masoebi kapa likhothaletso tse ka senyang mokhoa oa ho theha.

Qala ts'ebetso ea ho bopa, ka hloko ho sebelisa khatello le mocheso ka nako e behiloeng ho theha letlapa la polasetiki hantle ka mokhoa o lakatsehang.

Hang ha sebopeho se phethiloe, sehlahisoa sa polasetiki se sa tsoa bōptjoa se siuoa hore se tiee le ho pholile ka har'a hlobo, pele se tsoela pele ho phunya lesoba, ho phunyeletsa ka bohale, le ho bokella ka mokhoa o hlophisehileng bakeng sa palletizing e bonolo.

Ntša Sehlahisoa se Feletseng:

Lekola sehlahisoa se seng le se seng se felileng ka hloko ho netefatsa hore se lumellana le sebopeho se hlokahalang mme se latela litekanyetso tse behiloeng tsa boleng, 'me u etse liphetoho tse hlokahalang ha ho hlokahala.

Tlhoekiso le Tlhokomelo:

Ha o qetile ts'ebetso ea tlhahiso, theola mochini oa thermoforming ebe o o khaola mohloling oa matla ho baballa matla le ho boloka polokeho.

Hloekisa liforomo le lisebelisoa ka botlalo ho tlosa polasetiki kapa litšila tse setseng, ho boloka nako e telele ea hlobo le ho thibela mefokolo e ka bang teng lihlahisoa tse tlang.

Kenya ts'ebetsong kemiso ea kamehla ea tlhokomelo ho hlahloba le ho fana ka lisebelisoa tse fapaneng tsa lisebelisoa, ho netefatsa hore mochine oa thermoforming o lula o le boemong bo botle ba ho sebetsa, o khothalletsa katleho le bophelo bo bolelele bakeng sa tlhahiso e tsoelang pele.